Information

| VS-type Axial Seal | |||||

|---|---|---|---|---|---|

| Material | NBR、 VITON | ||||

| Advantages | 1.High flexibility; resistant against oil, water, dust; suitable for eccentric shafts. | ||||

| 2.Designed stretching force up to 300%. During installation, it can bypass the shaft key, gear and relevant protrusions. | |||||

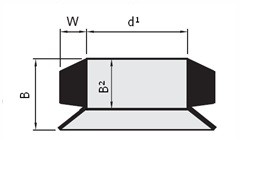

| Code of VS-type Seal | C Applicable Shaft Dia. |

d¹ Seal ID |

W Seal Height |

B² Inner Ring Thickness |

B Seal Width |

| VS- 5 | 4.5~5.5 | 4 | 2 | 3.9 | 5.2 |

| VS- 6 | 5.5~6.5 | 5 | 2 | 3.9 | 5.2 |

| VS- 7 | 6.5~8.0 | 6 | 2 | 3.9 | 5.2 |

| VS- 8 | 8.0~9.5 | 7 | 2 | 3.9 | 5.2 |

| VS- 10 | 9.5~11.5 | 9 | 3 | 5.6 | 7.7 |

| VS- 12 | 11.5~13.5 | 10.5 | 3 | 5.6 | 7.7 |

| VS- 14 | 13.5~15.5 | 12.5 | 3 | 5.6 | 7.7 |

| VS- 16 | 15.5~17.5 | 14 | 3 | 5.6 | 7.7 |

| VS- 18 | 17.5~19 | 16 | 3 | 5.6 | 7.7 |

| VS- 20 | 19~21 | 18 | 4 | 7.9 | 10.5 |

| VS- 22 | 21~24 | 20 | 4 | 7.9 | 10.5 |

| VS- 25 | 24~27 | 22 | 4 | 7.9 | 10.5 |

| VS- 28 | 27~29 | 25 | 4 | 7.9 | 10.5 |

| VS- 30 | 29~31 | 27 | 4 | 7.9 | 10.5 |

| VS- 32 | 31~33 | 29 | 4 | 7.9 | 10.5 |

| VS- 35 | 33~36 | 31 | 4 | 7.9 | 10.5 |

| VS- 38 | 36~38 | 34 | 4 | 7.9 | 10.5 |

| VS- 40 | 38~43 | 36 | 5 | 9.5 | 13 |

| VS- 45 | 43~48 | 40 | 5 | 9.5 | 13 |

| VS- 50 | 48~53 | 45 | 5 | 9.5 | 13 |

| VS- 55 | 53~58 | 49 | 5 | 9.5 | 13 |

| VS- 60 | 58~63 | 54 | 5 | 9.5 | 13 |

| VS- 65 | 63~68 | 58 | 5 | 9.5 | 13 |

| VS- 70 | 68~73 | 63 | 6 | 11.3 | 15.5 |

| VS- 75 | 73~78 | 67 | 6 | 11.3 | 15.5 |

| VS- 80 | 78~83 | 72 | 6 | 11.3 | 15.5 |

| VS- 85 | 83~88 | 76 | 6 | 11.3 | 15.5 |

| VS- 90 | 88~93 | 81 | 6 | 11.3 | 15.5 |

| VS- 95 | 93~98 | 85 | 6 | 11.3 | 15.5 |

| VS- 100 | 98~105 | 90 | 6 | 11.3 | 15.5 |

| VS- 110 | 105~115 | 99 | 7 | 13.1 | 18 |

| VS- 120 | 115~125 | 108 | 7 | 13.1 | 18 |

| VS- 130 | 125~135 | 117 | 7 | 13.1 | 18 |

| VS- 140 | 135~145 | 126 | 7 | 13.1 | 18 |

| VS- 150 | 145~155 | 135 | 7 | 13.1 | 18 |

| VS- 160 | 155~165 | 144 | 8 | 15 | 20.5 |

| VS- 170 | 165~175 | 153 | 8 | 15 | 20.5 |

| VS- 180 | 175~185 | 162 | 8 | 15 | 20.5 |

| VS- 190 | 185~195 | 171 | 8 | 15 | 20.5 |

| VS- 199 | 195~210 | 180 | 8 | 15 | 20.5 |